Accessories for traversing applications

We also offer accessories for our linear drives for wire and cable traversing applications: the Tension Control - a dancer used to control the material tension - and the multi-sized Guide System as "HGS" and “GS” with elements that can be customised to the winding task in question.

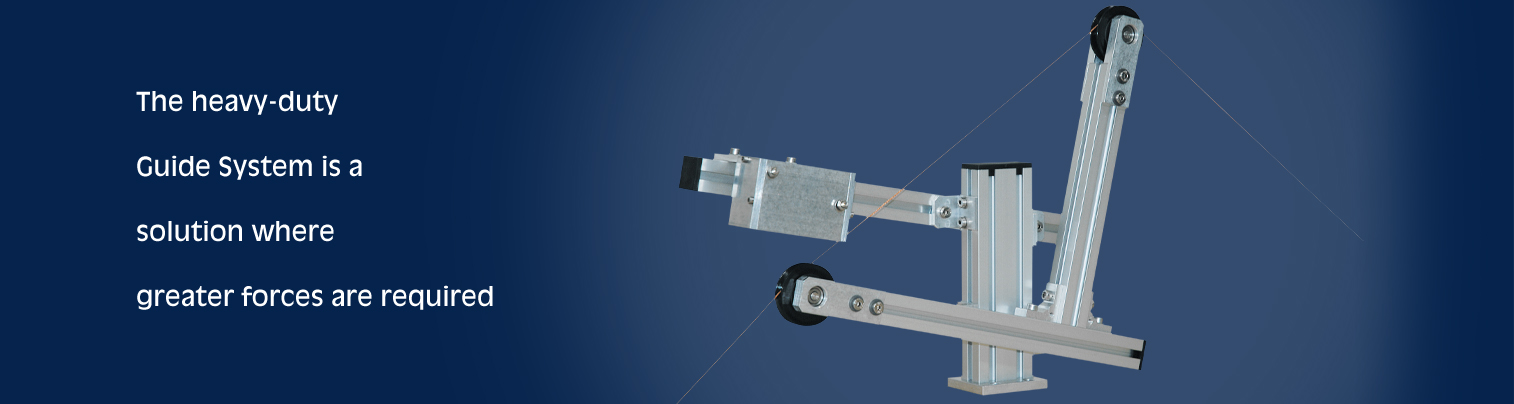

Guide System HGS

The Uhing HGS is optimally suited for higher tractive forces. This special HGS design is intended for the RG15, RG20, and RG30 types. Appropriate adapter plates ensure the material is always guided centrally to the rolling ring drive.

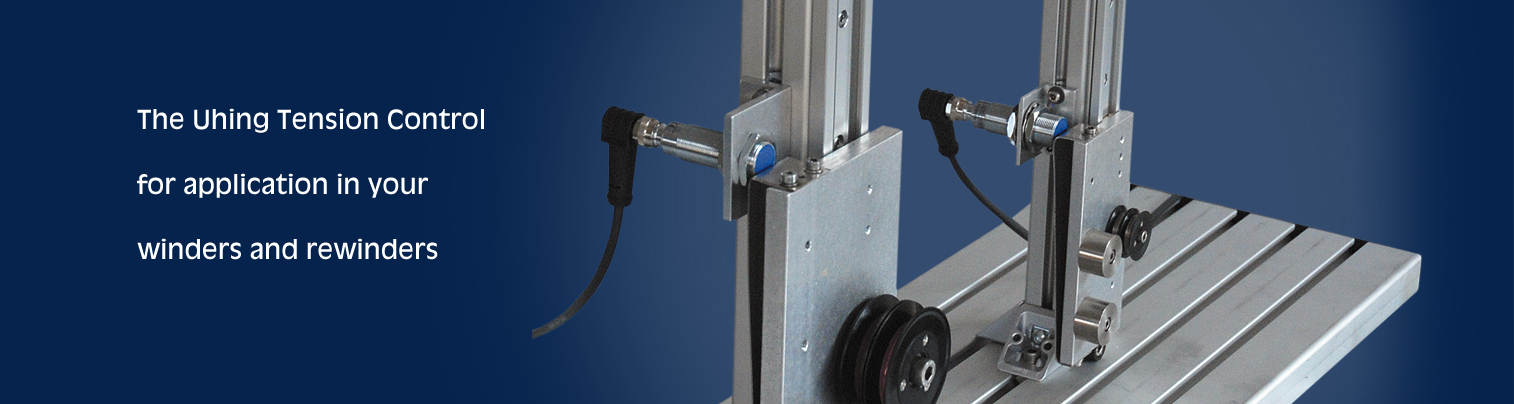

Uhing Tension Control

Uhing Tension Control is a dancer system that does not translate the dead weight of the material into a tension force but uses an external force that acts on the material.

A dancer is a commonly known method of controlling the tension when winding material. As a rule, a motor drives the spool to be wound at a given speed depending on the type of material.

The unwinder has to operate at a synchronised speed to ensure the desired tension force is present at all times. The Uhing Tension Control ensures a constant tension by way of a carriage on which weights are mounted. In this way, an accelerating winder will cause the Uhing Tension Control carriage to move in upward direction whereas slower winding will cause the carriage to move down.

According to the block and tackle principle, the tension is proportional to the dancer force. Uhing Tension Control can be adjusted using several pulleys and larger weights while the sensor at the carriage provides additional information for the drive motors and their speed control. The tension of the material has to be kept constant to prevent flaws in the winding pattern. Uhing Tension Control can be used for round and flat material.

By adding sensors to the Uhing Tension Control, it is possible to adjust the tension force and capture the material speed or to integrate a length counter system (special accessories).

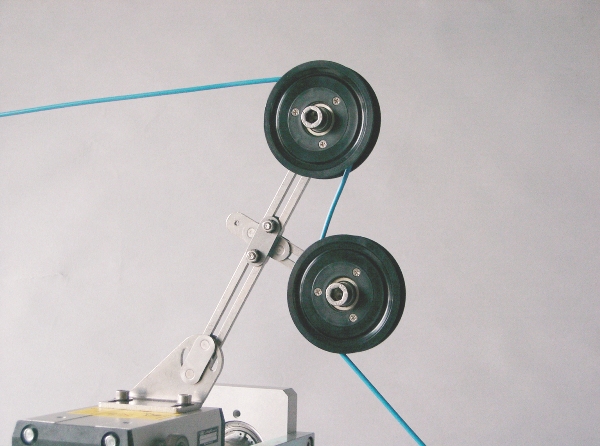

Uhing® guide system GS

Uhing® guide system GS transmits the traversing movement of the traversing unit to the guide roller and the material to be wound. Additional modules allow the system to be universally matched to the winding task.

Advantages

- Modular construction for easy adaptation to the winding task

- Continuously adjustable

- Torsionally rigid

- Adapter for assembly on Uhing rolling ring drives RG15, RG20, RG22 and RG30

- Made entirely of stainless steel

- Versatile attachment options for guide rollers

- Suitable for all traversing systems

Various application options for winding and traversing

The fastening devices of the GS system can be variably combined.

The varying lengths of the guide levers, the fastening devices as well as the angle as connection to the winding system allow the individual customization.