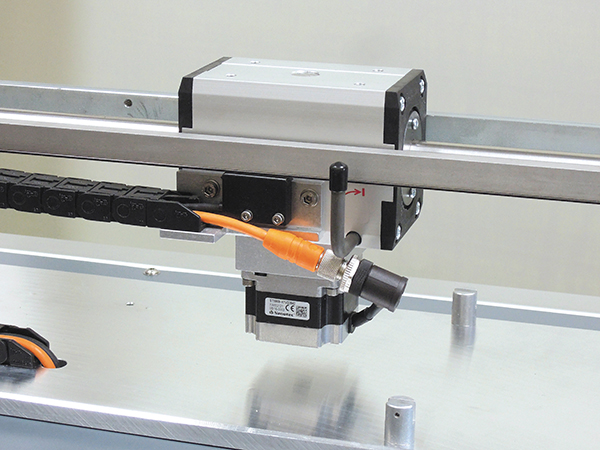

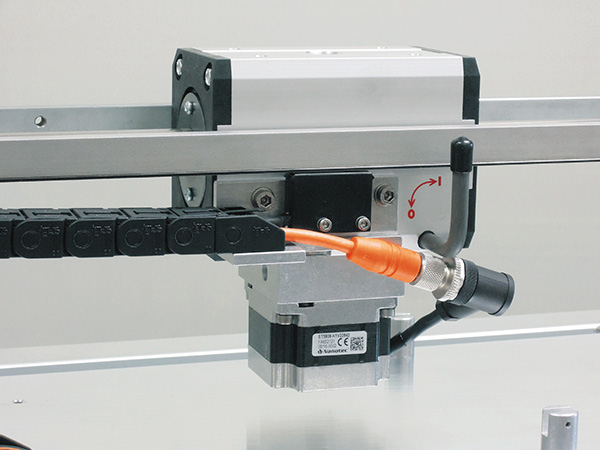

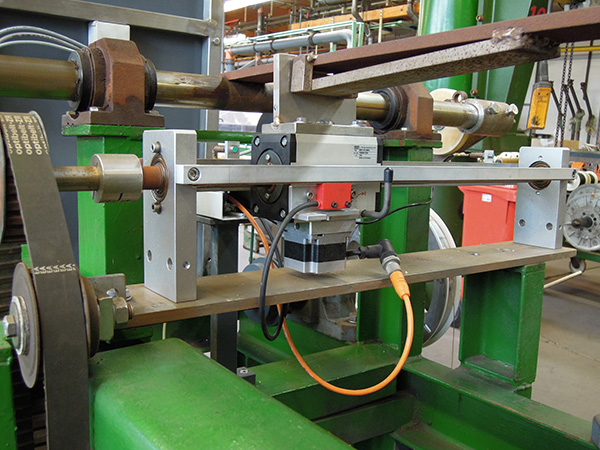

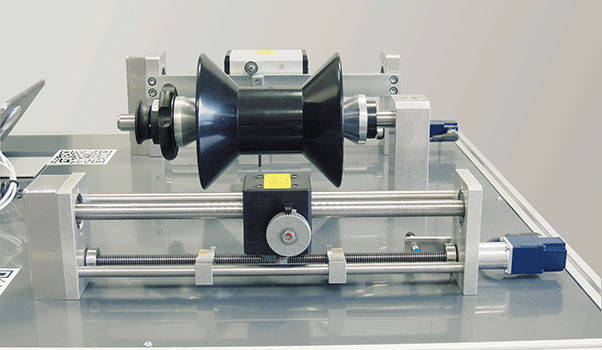

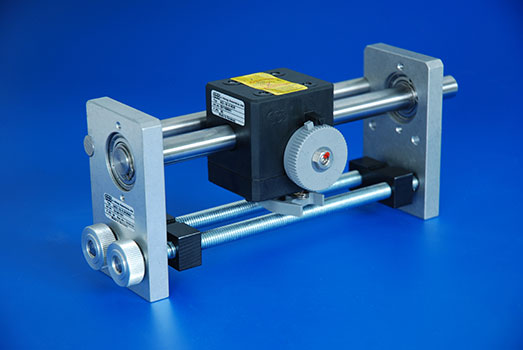

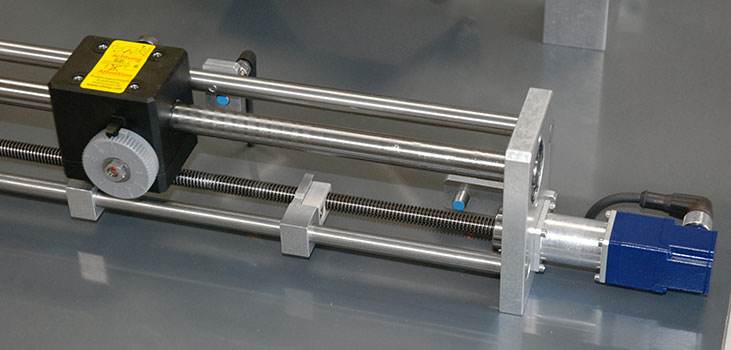

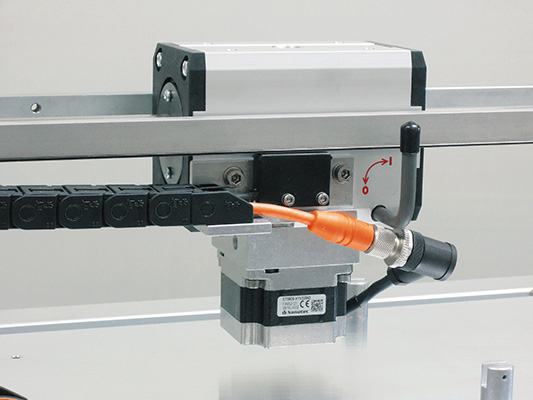

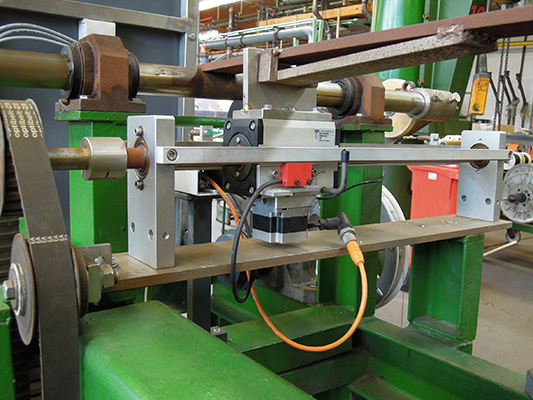

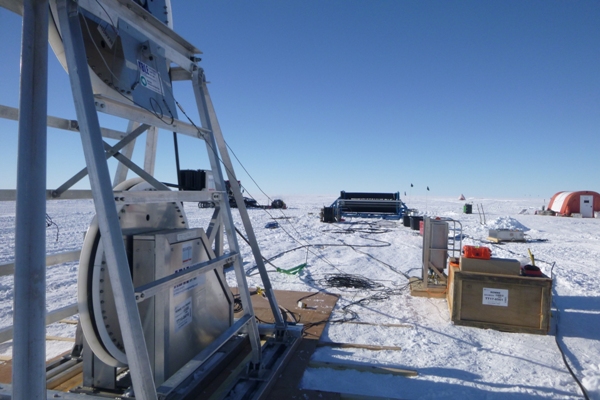

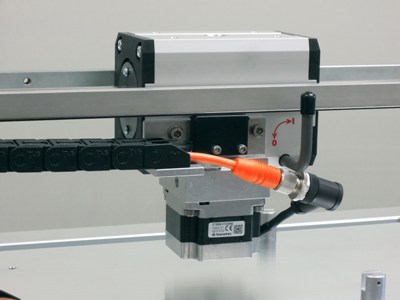

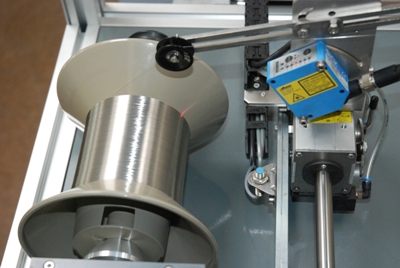

Uhing rolling ring drives are a real alternative to drives based on timing belts and threaded spindles whenever a permanent reciprocating movement is required during production and operation. Applying automated solutions, the specialists also help to develop prospective processes of high efficiency and quality.

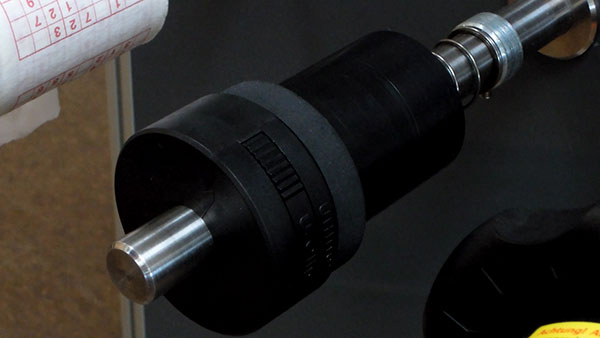

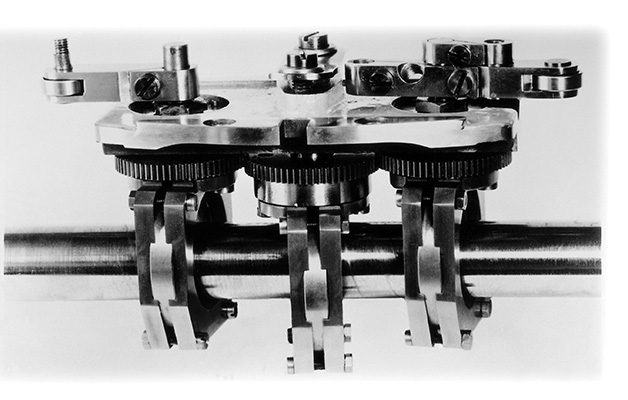

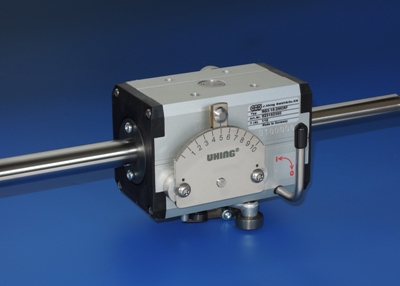

“The non-positive drive translates the movement of a rotating plain shaft with constant speed and direction of rotation into a stroke movement of the rolling ring drive”, Wolfgang Weber, Uhing’s Managing Director points out the basic principle of the rolling ring drive. Speed and stroke length are flexibly adjusted via the pitch values. The integrated reversing mechanism with adjustable stop ensures highly dynamic stroke reversal.

Entire article:  Automation: Uhing Motion Rolling Ring Drive

Automation: Uhing Motion Rolling Ring Drive