Uhing Drives Antarctic Research

Operating in one of the harshest environments on the planet, The British Antarctic Survey (BAS) has, for over 60 years, undertaken the majority of Britain’s scientific research on and around the Antarctic continent. A component of the Natural Environment Research Council, BAS supports three permanent research stations based in Antarctica, along with two stations on South Georgia and is at the forefront of research on “the frozen continent”, work that recognises that “the Polar Regions may be at the ends of the Earth but what happens there affects us all”.

BAS’s operations are managed and co-ordinated from their headquarters in Cambridge, UK.

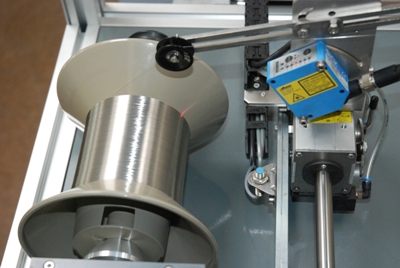

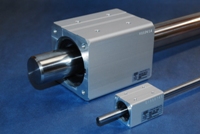

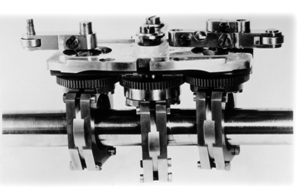

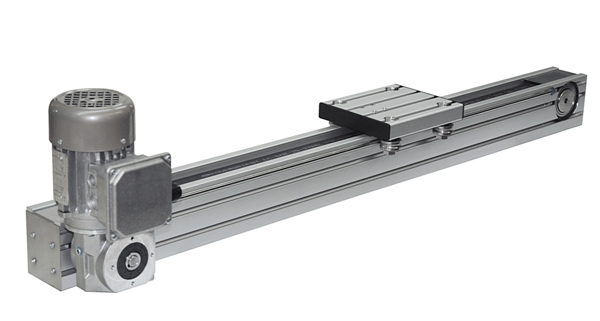

When a requirement for hose handling in the extreme conditions of West Antarctica was identified, BAS called on Techna International Ltd.’s extensive experience to assist in the design of a bespoke winding system to be built by ABLE Engineering Ltd.

Entire article: ![]() Uhing Drives Antarctic Research

Uhing Drives Antarctic Research

Source: Techna International Ltd, www.techna.co.uk

Press-Release July 2011

Press-Release July 2011

Press-Release February 2010

Press-Release February 2010